Automate, streamline, and improve with an easy to install and proven RFID solution

Whether it’s business to consumer or business to business, the challenges are the same. The costs associated with manual processes and correcting errors are high. The case is the same whether it is between your company’s own warehouses and stores, internal departments, from raw material to production, or similar. Also, it negatively affects customer experience when companies do not comply with promised delivery times.

Pick from inventory

Verify content

(un)load to correct location

Can you relate to these challenges?

- Experiencing manual and time-consuming scanning of goods

- Experiencing errors in your supply chain

- Wrong deliveries affecting your overall cost

- Lack of customer experience status

- Shrinkages between touchpoints

- Quality in processes

Taking supply chain automation to the next level

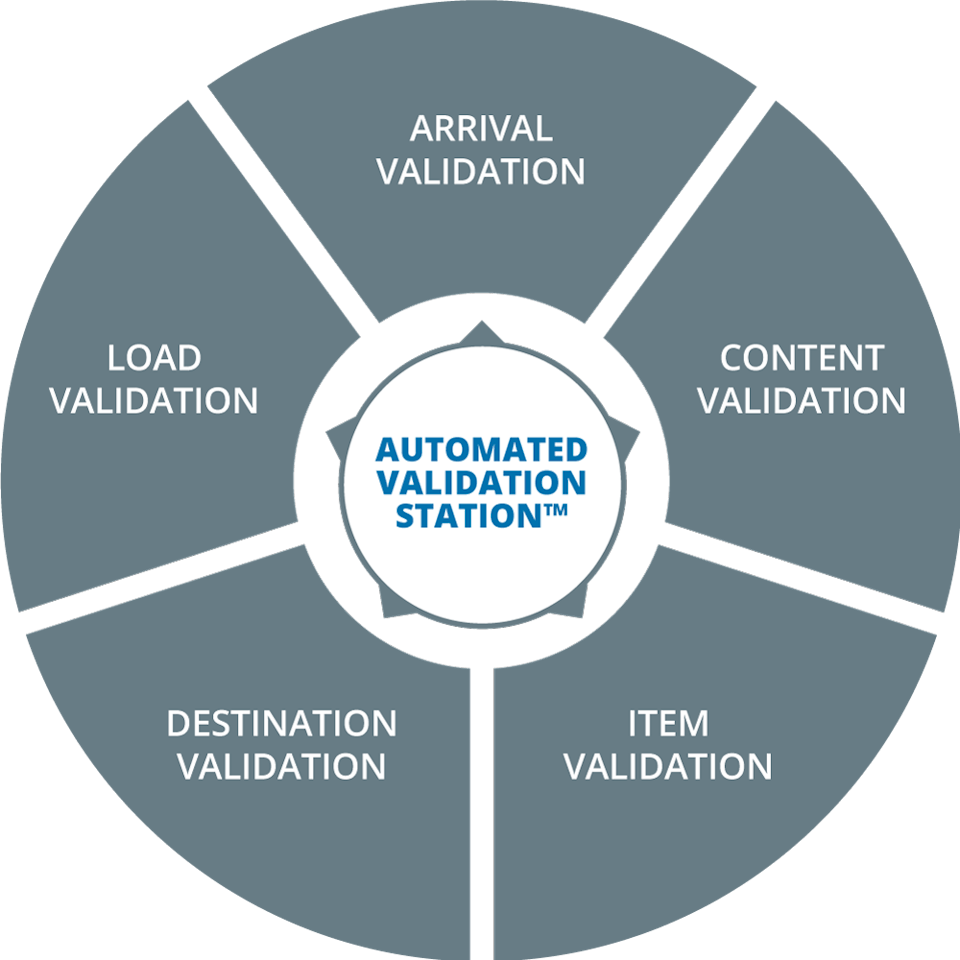

Applying Automated Validation Station™ (AVS), based on RFID technology for your existing processes, enables real-time automated scans while goods are ‘live’ in your logistic flow.

Automated Validation Station™ uses data from your current system(s) to automate your processes. Combining these data with data from the applied RFID results in an automated tracking and validation system. The solution contains three main components: A passive RFID tag, an RFID reader with antennas, and the AVS software component.

Software – AVS component

In LIVE Logistics™, the real magic happens when the RFID data are combined with data from your systems—performing a real-time linking between your data (production order, picking list, shipment order, or similar) and the automatic RFID reading by the installed RFID hardware.

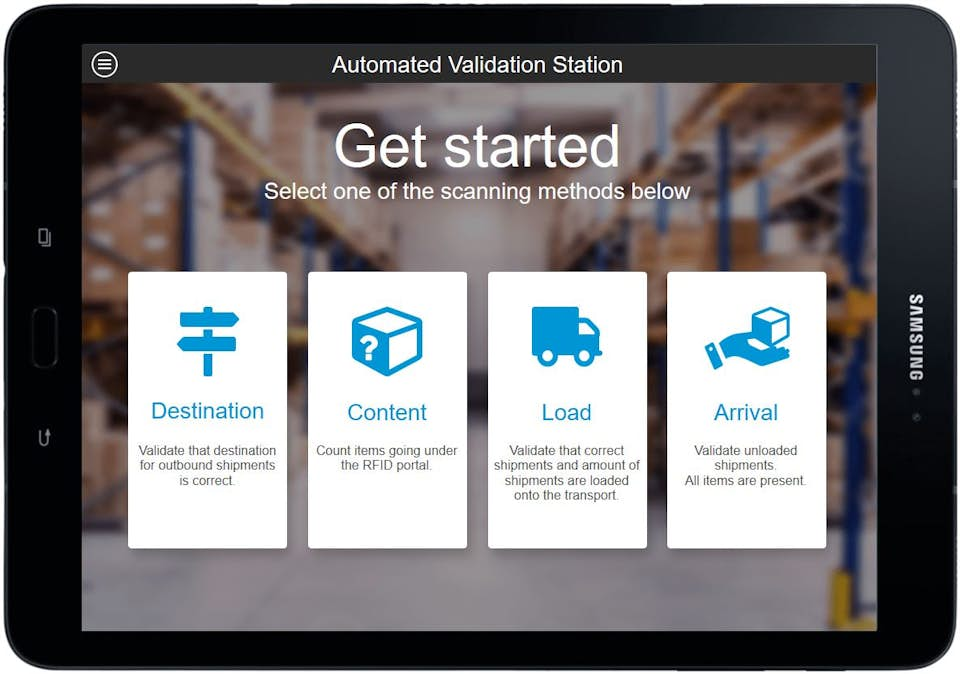

- The AVS solution logic is flexible and used for multiple purposes where an automated validation process is needed. Examples of validations:

- whether the goods are going to the correct destination or are misplaced,

whether all items are present and with no extras, - any other custom-made validation logic you want in the solution.

The fundamentals of the solution are that it can easily integrate with your existing systems – whether it’s a separate warehouse management software or ERP solution. The Automated Validation Station is non-invasive, as it is stateless and solely relies on data retrieved from your existing systems combined with the RFID readings and applied logic in our LIVE Logistics™ platform.

Hardware

The solution also carries a hardware part being either an RTLS RFID Portal™ or an RTLS RFID Process Reader.

The RFID reader receives all the data transmitted by the tag in real-time, then all raw materials, items, packages, or pallets are automatically scanned in your logistic flow.

After that, data are sent directly from the reader to our cloud backend platform, LIVE Logistics™, where the AVS component:

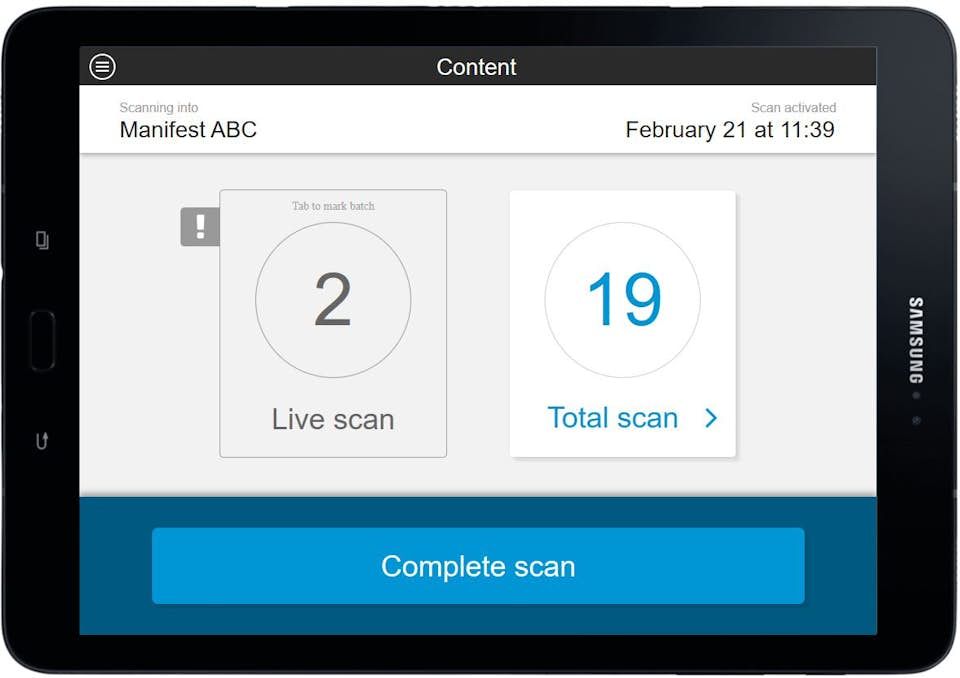

- Registers the automated scans

- Performs the validation logic before the scanned object leaves its current location

Passive RFID tag

The RFID tag is the identifier to track the raw materials, items, packages, or pallets across the logistic flow. Unlike a barcode, the RFID tag does not need to be within the reader’s line of sight. And hence that the hardware can perform an automated scan.

Automating your logistics with automated validation station

By introducing RFID technology and the AVS solution into your logistic flow, you will be able to automate and seamlessly deliver value such as:

- Improve item visibility and data accuracy

- Remove or complement existing technologies for registration of goods (barcode)

- Reduce errors in your supply chain as they occur in real-time

- Real-time flow of goods registration in your supply-chain

- Add automatic notification to the receiver when the parcel is handled/shipped.

- Automatic notification when the package has arrived and is ready for pick-up at location

- Documentation of consignment handover

Automating your logistic flow with our solution enables your company to deliver the expected improved supply-chain experience, whether you operate in B2B or B2C market segments.

A concept ready to go

- Simple implementation – ready to go concept based on building blocks

- Cloud-based solution – no on-premises software installation needed

- Proven integration to major WMS or ERP systems

- Easy scalability from pilot to the full-scale concept – vertical and horizontal

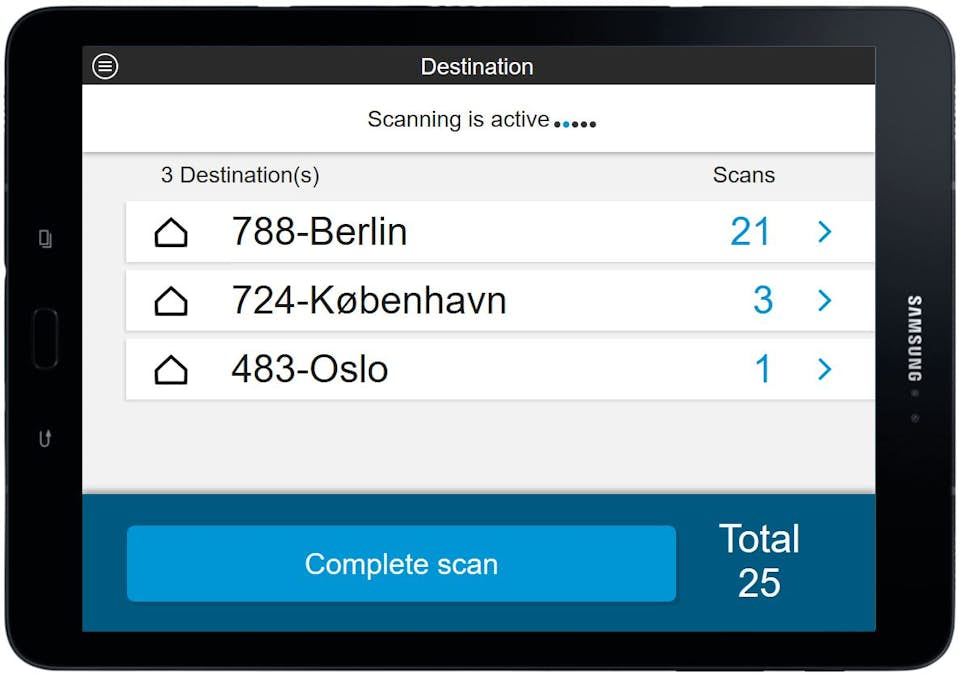

- Modern and flexible UI based on responsive HTML 5.0 platform for user interaction

- RFID and barcodes can work as complementary technologies in your processes

Step by step example from production to store using Automatic Validation Station™

Step 1: Apply RFID label to your goods early in the supply chain flow (production)

Step 2: Validate content – correct amount and no extras and aggregation by applying pallet label

Step 3: Validate and track the right pallets are going to correct destination/transport

Step 4: Automated arrival scan at warehouse of all goods

Step 5: Automated reception and update of inventory in WMS system

Step 6: Built pallet for customer based on the picking list

Step 7: Validation of destination of all SSCCs and content

Step 8: Validating and tracking that correct pallets are going onto the right transport.

Step 9: Automated arrival scan at the location of all goods and automatic WMS update

Want to be assured that AVS fits your setup?

Contact us to review your case and we will find a solution through real-time tracking and traceability.

Discover AVS in use