Why use Manual Image Capturing Station™?

When complexity and data capturing requirements increase, so does the need for effective and intelligent solutions for overcoming the added workload to avoid consignments piling up and pushing the problem downstream creating unnecessary interventions that put pressure on the entire operation.

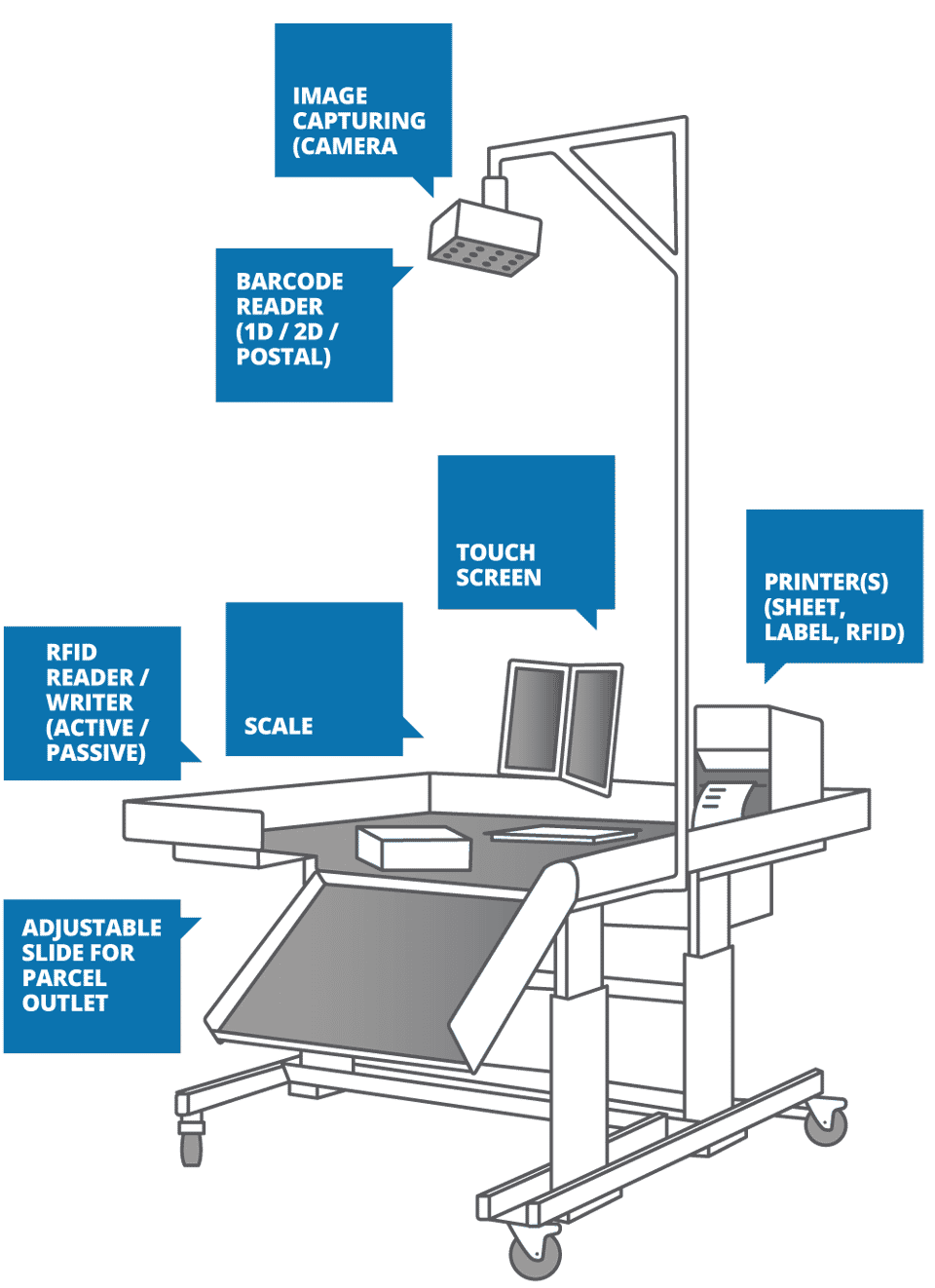

Manual Image Capturing Station™, or MICS for short, features a combination of smart camera technology and the latest machine-learning-based OCR, which will significantly increase your speed of data capturing and keep you in control of growing cross-border e-commerce volumes and the increase in complexity of the initial classification.

Scalable and flexible

Automatic data capturing

Full integration

How to navigate in times of transition

In 2021 changes relating to BREXIT, ICS2, EU VAT and more have added a significant extra layer of complexity to the import of e-commerce, while at the same time ITMATT data availability and quality have not yet reached a level of maturity that enables fully automated processing.

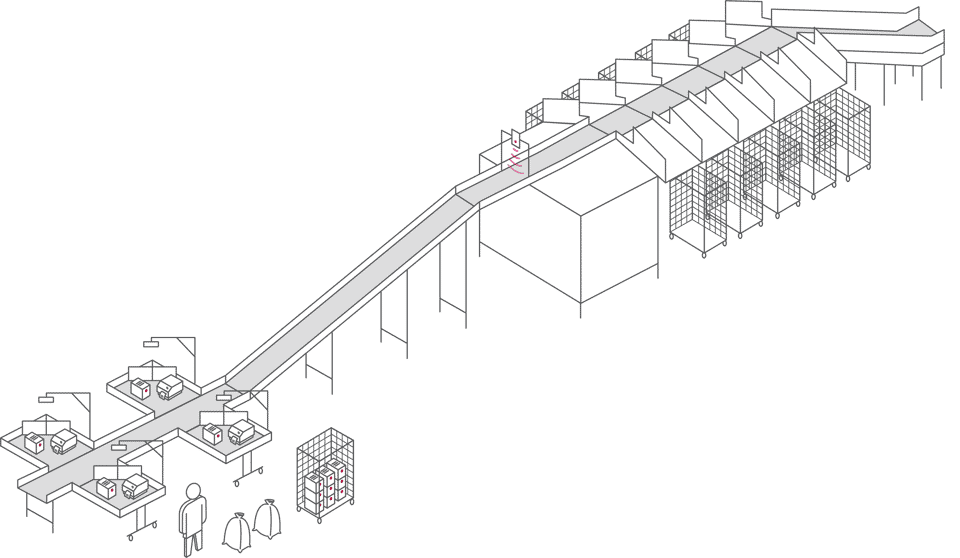

The MICS solution offers a balanced solution, where investment is relatively low, the solution fits into existing processing space and the solution is highly (and quickly) scalable to changes in volume and complexity.

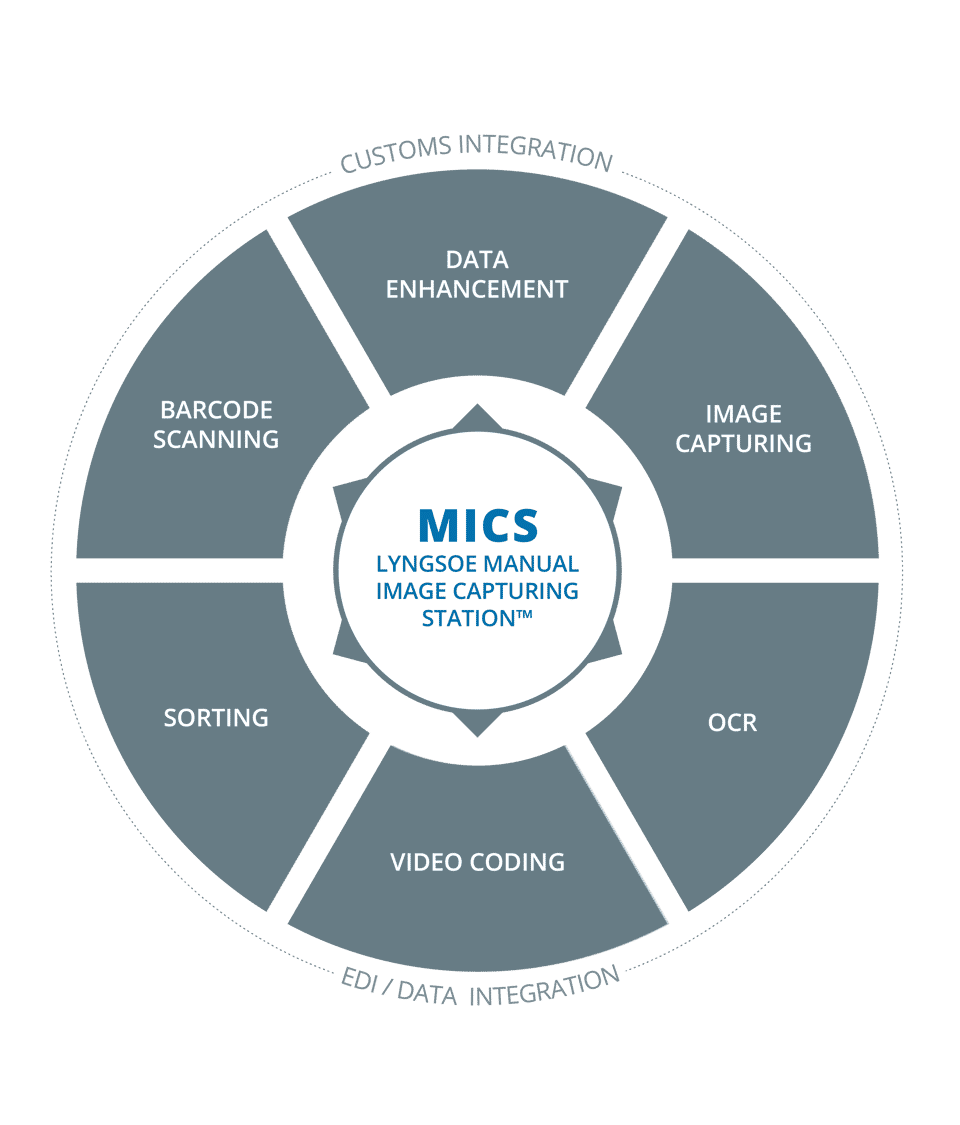

Using MICS as front-line data recording stations not only automates the reading of label data but also makes it possible to combine this data with ITMATT data, DDP data (delivered duty paid) and pre-clearance information, and other available data, which enables shipments to bypass heavy import and warehousing processes and go straight to distribution instead.

Optimization of time-consuming processes

Manual Image Capturing Station™ (MICS) lowers the cycle time of the import process by combining and automating arrival registration, data capturing, customs classification and VAT collection, and sorting into one single frontend process.

The MICS is available with different levels of automation from manual registration stations to fully automated sorting solutions and with different data collection capabilities from manual data entry to automatic OCR based on machine learning.

Integration with existing systems

Automated sorting

Besides fulfilling all the data capturing needs of importing e-commerce items, the MICS solution also offers automated sorting as a cost-effective add-on function. The sorting machine has a modular construction that is easy to adapt to the individual needs of each client. The system is scalable by design and can be expanded, adding more discharge points as the need changes over time.

Ergonomic work environment

Increase your speed of data capture

If you want to regain your control of your growing cross-border e-commerce volumes, then we are here to help.

Discover MICS