Leveraging technology for a seamless fashion journey

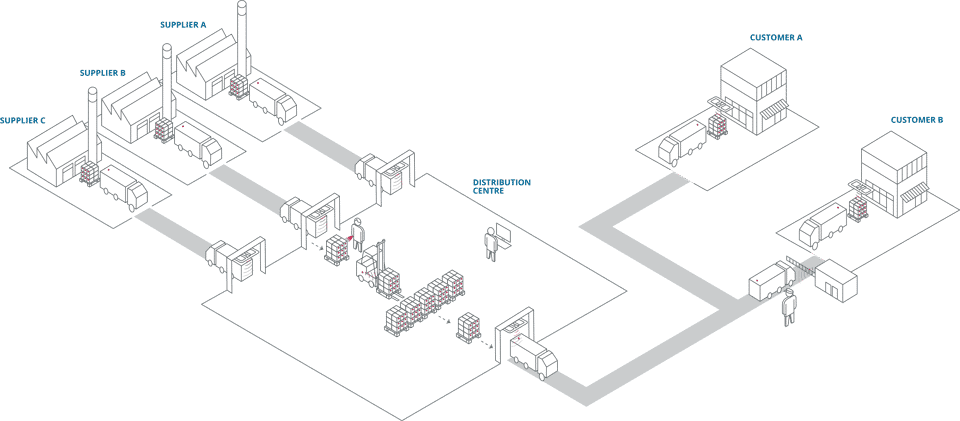

In the world of fashion, the journey from fabric to finished garment is complex and varied. To help navigate this intricate process efficiently, track and trace technology has emerged as a real game-changer. Radio Frequency Identification (RFID) in particular has been quietly revolutionizing the apparel supply chain, offering unprecedented visibility and control from the point of manufacture through to the retail floor.

Lyngsoe’s Business Development Executive, Sean Stephens, explores the concept in more detail and looks at how leading retailer Marks & Spencer have been able to streamline their operations and enhance the customer experience by using RFID to manage their supply chain.

The role of RFID in the apparel supply chain

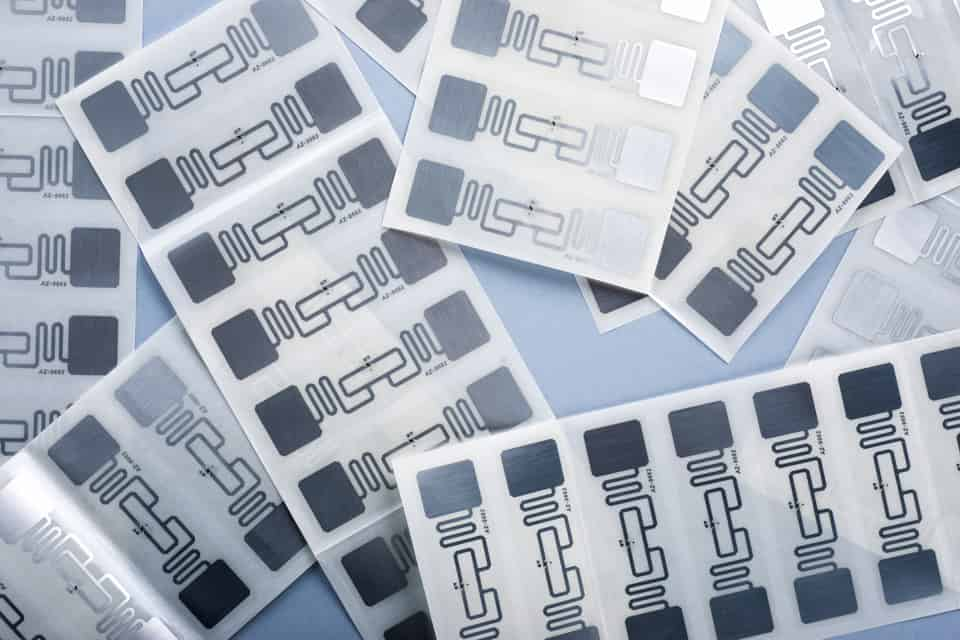

RFID technology involves embedding small, wireless tags into items, which can be read by radio waves. These tags provide a unique identifier for each item, allowing for real-time tracking throughout the supply chain - Lyngsoe’s Asset Tracking technology is a great example of this. When used in the apparel industry, the RFID tags are attached to garments immediately after manufacture and scanned at regular intervals. This early tagging ensures that every item can be monitored through each stage of its journey—production, distribution, and retail.

The benefits of real-time track and trace

These RFID tags, particularly when used in conjunction with technology like our Smart Warehouse solution, offer a host of benefits for retailers looking to have better visibility over their supply chain. Often when new customers are looking at our software making cost savings is the key driver, but there are also a number of additional benefits that can be achieved, including -

- Enhanced inventory management - RFID provides retailers with accurate, real-time data on inventory levels. This means knowing exactly which items are available, in transit, or out of stock, allowing for better inventory control and reducing the risk of overstocking or stockouts.

- Increased supply chain visibility - By tracking items from the source, RFID enables end-to-end visibility, so you can monitor the movement of garments from factories to distribution centers and stores, ensuring timely deliveries and reducing lead times.

- Improved accuracy and efficiency - Manual scanning and inventory checks are time-consuming and prone to errors. RFID automates these processes, enhancing accuracy and freeing up retail staff to focus on customer service and other value-added activities. The same also applies to warehouse operatives who previously would have lost hours locating items and scanning products.

- Better loss prevention - RFID tags help in minimizing losses due to theft or misplacement. With real-time tracking, you can quickly identify discrepancies and address potential issues before they escalate.

- Enhanced customer experience - With precise inventory data, you can ensure popular items are always in stock and readily available, which as we know leads to an increase in sales as well as supporting customer satisfaction.

Marks & Spencer: Leading by example

Marks & Spencer (M&S) has been at the forefront of integrating RFID into its supply chain and their adoption and championing of the technology is something I have followed closely over the past few years. By tagging their items at the source post-manufacture, they ensure that every garment can be tracked throughout its lifecycle. The wide scale implementation has resulted in a number of tangible benefits for them:

- Stock accuracy - According to Retail Technology Magazine, the move to RFID tagging has translated in to inventory accuracy improvements of up to 50%, and out-of-stock cuts of 30-40% - all of which translates to better stock availability for customers.

- Operational efficiency - The automation of inventory management processes has reduced labor costs and operational inefficiencies. These types of results are typical of those we see our customers achieving quickly following implementation.

- Sustainability - With better inventory control, M&S have been able to reduce waste by minimizing overproduction and excess inventory.

The future of fashion

The increasing adoption of RFID technology for the apparel supply chain shows how real-time track and trace can really transform the industry. For retailers like M&S, this innovation has given them a competitive edge by enhancing efficiency, accuracy, and customer satisfaction. As the fashion industry continues to grow and evolve, and attention turns more to the technology available to support it, I strongly believe the integration of RFID at the earliest stages of the manufacturing process will undoubtedly play a pivotal role for retailers looking to get closer to their supply chain.

Transform Your Supply Chain with Lyngsoe Systems

If you're ready to transform your supply chain, I'm here to help. Contact me today to learn more about how Lyngsoe Systems can assist you in achieving real-time inventory tracking and improved accuracy. Let's work together to transform your retail operations and deliver unparalleled customer experiences.

FAQ

What is real-time track and trace in the apparel supply chain?

Real-time track and trace refers to the use of technologies like RFID and RTLS to monitor and record the movement of materials and products, allowing immediate visibility of the location and status of items from raw fabric to finished garments.

How does real-time tracking benefit apparel manufacturers?

By implementing real-time tracking, manufacturers can reduce production delays by identifying bottlenecks promptly, enhance inventory accuracy, minimizing overstock or stockouts and ensure timely delivery of products to retailers.

Can real-time tracking improve sustainability in the fashion industry?

Yes, by providing accurate data on inventory and production processes, companies can reduce waste by avoiding overproduction, optimize resource utilization and enhance transparency, allowing for more sustainable sourcing and manufacturing practices.