Transform Your Warehouse with the Smart Warehouse solution

Unlock the power to run a more efficient warehouse and deliver an outstanding customer experience, no matter the demands on your operations. With our Smart Warehouse solution, you can streamline processes, lower costs, and meet high service standards - all from a single, integrated solution.

In today's competitive landscape, staying ahead requires more than just meeting expectations – you need to exceed them. Our Smart Warehouse solution empowers operators to drive efficiencies across the board, enabling faster, more accurate order fulfilment while delivering top-tier service for retaining and winning business. Automate critical processes, reduce operational costs, and gain real-time visibility into your entire operation.

With Smart Warehouse, you can lower costs and boost customer satisfaction simultaneously. The solution maximizes efficiency, prevents costly mis-shipments and transport delays, and frees up capacity to support business growth. Real-time location tracking and condition monitoring of inventory allow operators to meet customer SLAs, uphold quality requirements, and enhance operational reliability.

Key Benefits

- Maximize space utilization by enhancing utilization of warehouse capacity.

- Cut labor costs by reducing manual handling and staffing needs, allowing you to reallocating resources where they matter most.

- Eliminate costly errors through real-time tracking, minimizing mis-shipments and returns.

- Improve SLA performance through 24/7 inventory tracking, improving on-time performance and customer satisfaction.

- Enhance customer loyalty with seamless operations that build trust, reduce complaints, and elevate customer satisfaction.

- Protect sensitive goods with real-time alerts to ensure optimal storage and transit conditions for temperature-sensitive items.

Embrace the Smart Warehouse solution to elevate your operations and deliver the best possible experience to your customers.

1-800-Flowers Blooms with Smart Warehouse Technology

The 1-800-Flowers team is committed to delivering a best-in-class experience for their customers and consistently invests in innovative solutions to enhance customer interactions with their brands. This commitment includes the adoption of Lyngsoe Systems, Smart Warehouse technology, which helps the 1-800-Flowers team elevate the customer experience by consistently ensuring the finest selection of beautiful flowers and gifts are available for same-day or next-day delivery across the United States.

The Smart Warehouse powered by Lyngsoe LIVE Logistics™ has helped improve inventory and operational efficiencies, especially during the busiest times of the year.

"We’ve experienced significant improvements in our operations, including increased efficiency and reduced waste, which have helped streamline our processes and positively impacted customer satisfaction. This technology helps us focus on our vision of inspiring our customers to give more, connect more, and build more and better relationships.” - 1-800-Flowers Team Manager

The implementation of the Smart Warehouse solution, with RFID tracking has helped reduce the time required by warehouse operators, allowing their teams to work more efficiently. It has also helped streamline training processes, minimizing the need for extensive instruction and supervision of seasonal workers. Additionally, 1-800-Flowers has achieved high fulfillment accuracy rates, leading to enhanced customer satisfaction. The Smart Warehouse solution has also yielded considerable cost savings by lowering RMA handling costs and reducing waste during order fulfillment.

By choosing Smart Warehouse powered by Lyngsoe LIVE Logistics™, you are not just improving your warehouse operations - you are enhancing the entire customer experience too.

Enhancing Traditional WMS with Smart Warehousing

Many warehouses still rely on manual processes like data entry, inventory scanning, and order fulfilment, leading to errors, delays, and inefficiencies. Traditional methods often result in:

- Inaccurate inventory levels, causing overstock or stockouts.

- Picking errors and shipment mistakes, leading to customer dissatisfaction.

- Ineffective order processing, slowing down the entire supply chain.

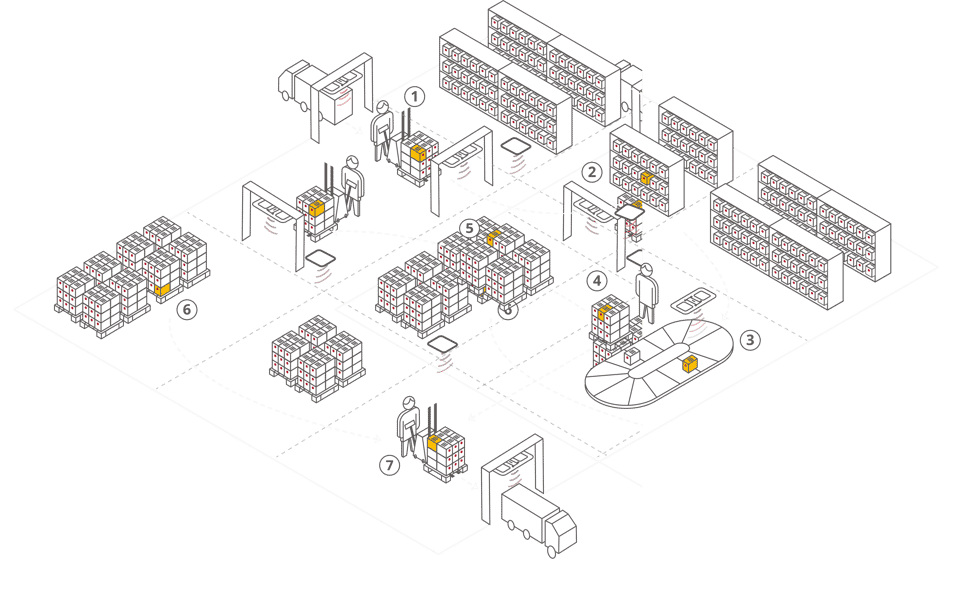

The Smart Warehouse, powered by Lyngsoe LIVE Logistics™, replaces outdated processes as it is an advanced, fully integrated solution designed to revolutionize how you track, manage, and locate items within your warehouse. By combining cutting-edge x-tracking web and app software, central RFID middleware, RFID Edgeware and multi-purpose RFID devices, our solution enables real-time visibility of inventory on shelves and floor locations in complex warehouses, ensuring unparalleled efficiency and accuracy in goods receipt, replenishment, picking, packing and shipping.

Here's why the Smart Warehouse solution stands out

Our solution offers and utilizes a comprehensive suite of tools (four to be exact), including RTLS hardware and RFID Edgeware, to keep your warehouse operating at peak efficiency:

- RTLS Smart Antennas: Installed between 6 and 15 meters high, perfect for real-time location detection and stock management at item, carton, and pallet levels.

- RTLS Portals: Installed at dock doors or process (choke) points to track goods in near real-time as they move.

- Versatile RTLS Handheld Devices: Enable barcode scanning and RFID encoding on the fly, seamlessly integrating with your current barcode systems.

- RTLS Readers: Stationary (fixed) or mobile, designed to track goods along conveyors, sorters, or mounted on moving vehicles such as forklifts and trucks.

Our RFID Edgeware performs first-level data processing, managing data filtration, zone and location calculations, and process point detection - ensuring seamless operation and accurate tracking.

Central RFID Middleware

Our RFID Edgeware and the Lyngsoe X-Tracking™ app on handheld devices push data to the Central RFID Middleware for advanced processing, event creation, and secure data storage. The middleware integrates seamlessly with existing Warehouse Management Systems (WMS) through REST APIs or custom interfaces, keeping your operations synchronized and fully optimized.

Comprehensive Device Management & Proactive Monitoring

Smart Warehouse ensures robust device management with full visibility and control over all RFID hardware and software. Centralized monitoring and automatic analysis and alerts proactively address potential issues, guaranteeing high uptime and uninterrupted operations for both RFID hardware and software. This proactive approach minimizes downtime and keeps your warehouse running smoothly.

Versatile Handheld Devices

You will be able to choose from two handheld device types:

- Barcode Scanning Only

- Barcode & RFID Scanning (writing and reading)

These devices streamline workflows with functions like Scan-Scan for linking barcodes to RFID tags, Lookup Location for rapid item finding, and Locate Item with RFID reading capabilities, making warehouse operations intuitive and efficient.

Seamless Integration & Support

Our platform integrates effortlessly with any Warehouse Management System through a REST API or other custom APIs as needed. Additionally, customers benefit from the Lyngsoe Customer Service and Support web portal, enabling easy ticket management and issue tracking.

Smarter Decisions with Data

Smart Warehouse doesn't just track—it transforms your data into actionable insights. By collecting and analyzing real-time information, you can:

- Optimize Inventory Workflows: Identify patterns and adjust strategies for stocking, picking, and replenishment.

- Identify Bottlenecks: Pinpoint inefficiencies in processes and take corrective action swiftly.

- Enhance Operational Performance: Make informed decisions that lead to continuous improvement and increased profitability.

Lyngsoe X-Tracking™ Application

Our web-based X-Tracking™ app provides real-time location tracking and visualization for all RFID-tagged goods within your warehouse. Key features include:

- Configurable Events: Customize alerts and notifications for Arrival Registration, Zone/Location Movements, Process Point Tracking, and Departure Registration.

- Powerful Reporting: Access detailed reports like Item Trace, Item Location, and Inventory Count to gain full oversight of goods' location and condition.

- User-Friendly Interface: Intuitive design ensures quick adoption and ease of use for your team.

Built for Every Industry

Smart Warehouse is tailored to meet the needs of diverse industries:

- Pharmaceuticals: Ensure compliance with temperature monitoring and traceability.

- E-commerce: Meet demand spikes with automated, error-free order fulfillment.

- Third-Party Logistics (3PL): Streamline operations for multiple clients with scalable solutions.

- Retail and Fashion: Optimize inventory management for fast-moving goods.

Protect and Monitor Sensitive Goods

For warehouses handling temperature-sensitive items such as pharmaceuticals or perishables, Smart Warehouse offers:

- Real-Time Temperature Monitoring: Ensure goods are stored and transported under optimal conditions.

- Immediate Alerts: Operators receive instant notifications of any deviations, allowing for prompt corrective action.

- Compliance Assurance: Meet regulatory requirements and maintain product integrity throughout the supply chain.

Monitor Sensitive Goods via Smart Warehouse

Warehouses handling pharmaceuticals, perishable goods, and any other items with strict temperature requirements, face the ongoing challenge of ensuring the preservation of the items at any given location. Our Smart Warehouse technology includes features such as start-the-clock/stop-the-clock to support the monitoring of your sensitive goods, ensuring they are in the right locations with the right temperature conditions.

As soon as any goods requiring a certain temperature level are on the move, alerts are sent directly to your operators. By prompting and tracking, you can ensure all temperature-sensitive items are being stored at the required conditions, in the right areas of the warehouse, helping ensure your goods reach their destination in the exact state they left your warehouse.

Team up with a full solution provider for warehouse optimization

We know that no two warehouse operations are the same and that warehouse management is one of the most important parts of the supply chain and holds a key function in increasing customer satisfaction, optimizing profits, and streamlining the handling of orders. The various processes that go on in a warehouse produce an enormous amount of data every day, from which you need to manage operations and make decisions to increase value for your customers and shareholders.

As a solution provider, we offer solutions for the entire asset flow, from capturing the data, identifying the asset, and presenting it as useful data, enabling you to improve your decision-making. With our solution, you will be able to know where every item is in real-time. It is fast, easy to implement, and fully scalable — no matter the warehouse’s challenges, layout, or size.

Our core business activity is to capture and filter data to make it easily accessible and present it in a value-added format for your business systems. Since different sensors and tag technologies offer different features, limitations, and advantages, our RTLS Platform is designed to collect, handle, and process unlimited amounts of data. Not only from RFID sources but from multiple tracking technologies.

The Complete Smart Warehouse Solution

The Smart Warehouse solution is more than just technology - it's a fully integrated ecosystem designed to streamline logistics operations and enhance accuracy. Choose Smart Warehouse powered by Lyngsoe LIVE Logistics™ to:

- Automate manual processes.

- Scale seamlessly.

- Maximize storage capacity and reduce waste.

- Enhance customer satisfaction with seamless order fulfillment.

- Ensure compliance for sensitive goods.

Discover how Smart Warehouse by Lyngsoe Systems can redefine your operations. Schedule a personalized demo today and start achieving measurable results.

How smart warehouses enable a successful Black Friday

Discover how smart warehouse solutions are the key to ensuring a profitable Black Friday season.

Our Success Stories