Achieve Full Visibility & Control of Your Assets

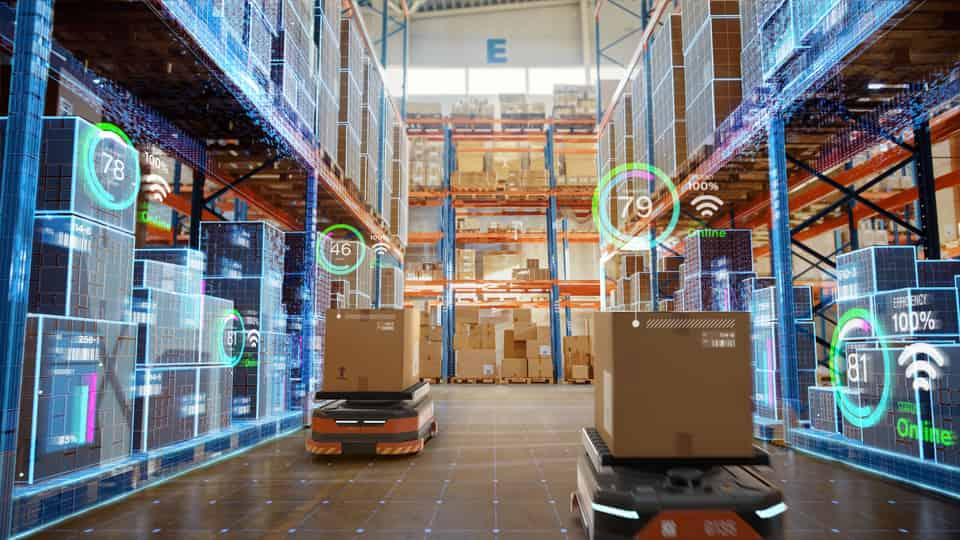

Gain complete visibility and control of your assets across your network and supply chain with our Asset Tracking and Flow Management solution. Ensure that assets like roll cages (transport containers with wheels) and other returnable containers used in transport, logistics, and manufacturing are always in the right place at the right time. With our solution, managing asset availability and location is effortless, empowering you to meet customer demands in a cost-effective and environmentally responsible way.

Key Benefits:

- Complete Visibility: Know exactly where your assets are at all times.

- Cost Efficiency: Eliminate unnecessary costs related to asset loss or replacement.

- Sustainability: Reduce CO2 emissions by optimizing asset usage and avoiding inefficient relocations.

- Operational Excellence: Prevent shortages, increase efficiency, and reduce operational costs.

Asset Tracking and Flow Management is your key to achieving operational excellence and business performance. Our solution helps prevent capacity shortages, reduce costs associated with lost or misplaced assets, and minimize expenses from buying replacement equipment. By optimizing asset placement and reducing unnecessary relocations, you also lower your environmental impact by lowering CO2 emissions, contributing to sustainability goals.

Real-time tracking and flow monitoring offer an accurate overview of asset locations, both within and outside your network, ensuring smooth and efficient operations. Optimize asset flow, right-size capacity, and unlock greater business potential with our Asset Flow Management solution powered by Lyngsoe LIVE Logistics™.

Get in Touch

Posti’s Journey to Operational Excellence with Asset Flow Management

“We responsibly deliver what matters to you—on your terms” . This vision is brought to life by Posti through unparalleled control and transparency of every item in their network. When customers trust Posti with their shipments transported in roll cages, they gain full visibility and flexibility, adapting to evolving delivery requirements throughout the Posti network.

Achieving this vision requires real-time visibility of every transport asset - whether it's a roll cage or a consigned shipment - moving through the network. By pinpointing the exact location of individual roll cages, Posti can adjust delivery details (such as time and place) on demand, ensuring a high level of service. Key to this capability is precise and automated tracking roll cages, whether they are inside Posti’s facilities, enroute, or at customer locations.

With precise and automated tracking through the use of our Asset Flow Management solution powered by Lyngsoe LIVE Logistics™, Posti delivers on their vision and customer promise, while also benefitting in other ways as the solution enables:

- Prevention of asset Loss: Reduces Posti’s need for costly replacement investments by avoiding the loss of roll cages.

- Optimization of capacity Use: Posti knows exactly where roll cages are and the capacity they provide, ensuring they are positioned in the right location at the right time to meet operational demand, minimizing the need to purchase additional assets like cardboard pallets.

- Reduction of environmental impact: Posti can lower CO2 emissions by eliminating inefficient asset relocations, thanks to full visibility of transport unit inventories. As well, full control of roll cage inventory paves the way for less need for more roll cages, thus CO2 emissions to produce those.

By leveraging the Asset Flow Management solution powered by Lyngsoe LIVE Logistics™, Posti not only meets but exceeds their promise, gaining significant business and environmental advantages.

How Our Asset Flow Management Solution Works

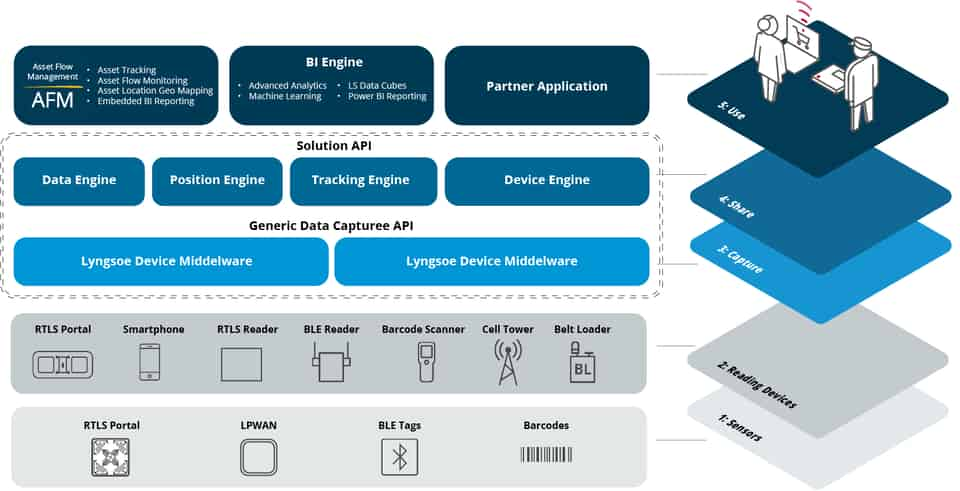

The Asset Flow Management solution, powered by Lyngsoe LIVE Logistics™, is an advanced, fully integrated platform designed to revolutionize how you track, manage, and locate assets such as roll cages and other types of returnable transport items (RTI). Using innovative technologies like our Lyngsoe X-Tracking™ web- and app software, central middleware, RFID Edgeware, BLE apps, and multi-purpose RFID and BLE devices, our solution provides real-time flow visibility of assets throughout domestic transport networks, supply chains, and at collection and delivery sites.

*The figure depicts the layers and components included in the turnkey Asset Flow Management solution.

Why Choose Asset Flow Management?

Our solution is scalable, utilizing multiple RTLS, RFID, and BLE technologies (hardware and software), which can be configured to meet your data capture needs and integrate with your existing infrastructure to fulfill individual customer needs.

- BLE/RFID Asset Tag: Long lasting, durable and built for harsh environments, combining BLE, RFID, and barcode data to provide real-time end-to-end tracking of assets. Supporting both inventory and flow management, as well as operational excellence with constant updates on asset locations. We specialize in designing custom tag housing that can enable faster deployment and optimal placement on your specific assets.

- RTLS BLE Handheld Devices: Combine mobile BLE and GPS data to provide precise location detection at delivery and collection points, even where fixed infrastructure isn’t feasible.

- RTLS BLE AoA Locators: Installed in building ceilings for enabling precise indoor positioning of assets, ensuring and supporting automated shipment consignments and process flow monitoring to ensure SLA and cut-off time compliance.

- RTLS RFID Portals: Installed at dock doors or process (choke) points to track moving assets in near real-time with RFID and optionally BLE.

- RTLS RFID Handheld Devices: Enabling barcode scanning and RFID encoding, ensuring seamless asset receipt and tracking on the fly utilizing existing customer barcodes.

The solution utilizes two BLE apps for mobile handheld barcode scanning devices (Android), used for registering assets into inventory and continuously tracking their locations. Our RFID Edgeware, on-board RTLS portals manages first-level processing, managing data, filtration, and zone, location and process point calculations, ensuring smooth operation and accurate tracking.

Asset Flow Management Web Frontend

The web-based Asset Flow Management frontend application, based on Lyngsoe X-Tracking™, provides real-time asset tracking and flow management across domestic transportation networks or supply chain setups. The system offers reports and features such as:

- A list of assets at their last known location, along with trace history.

- A search function for specific assets.

- Flow monitoring for assets moving in and out of specific locations.

- Exchange matrix showing asset movement (flow) between regions or locations.

- A graphical overview of roll cage volumes per location.

The Asset Flow Management application will store data for Assets for a given time to ensure data have been exchanged with the customer systems. Hereafter data will be discarded from the system.

Central RTLS Middleware

The BLE apps on mobile devices, RFID Edgeware, and the Lyngsoe X-Tracking™ app on handheld devices push data to the Central RTLS Middleware for advanced processing, which processes location data, creates events, and stores information. The Central RTLS Middleware also provides seamless API integration (via REST API) with existing ERP, BI, WMS, and TMS systems, ensuring all operations remain in sync and that data can be used effectively across platforms.

Comprehensive Device Management & Monitoring

Running a logistics platform requires robust device management. Our solution offers complete visibility and control over all tracking devices, regardless of the technology. With Lyngsoe LIVE Logistics™, you benefit from a centralized monitoring service that ensures high uptime for both hardware and software. Automated analysis and alerts help resolve issues proactively, minimizing device failures.

Use Your Existing Mobile Devices

Already using mobile handheld devices (PDAs or smartphones with Android 9 and BLE 5.1 or higher)? Our low-power BLE apps can be easily downloaded and used for Asset Flow Management. If needed, we also supply state-of-the-art PDAs and smartphones hardware too. The two BLE apps include:

Asset Registration App

Quickly links customer-specific asset IDs (barcode/QR) to asset tags through barcode/QR scanning on the asset and the barcode/QR printed on the Asset tag (same ID as the encoded RFID/BLE tag ID inside the Asset tag) enabling registration of the entire fleet of Asset under management.

Asset Tracking App

Captures the unique asset ID and GPS coordinates every 30 seconds, ensuring constant location updates with minimal impact on battery life, so with a fully charged smartphone/PDA at the start of the day, the driver will still be able to have a full operational day.

Seamless Integration & Support

Our platform integrates effortlessly with ERP, BI, WMS, and TMS systems through a REST API or other suitable APIs. Additionally, customers gain access to the Lyngsoe Customer Service and Support web portal for easy ticket management and issue tracking.

The Asset Flow Management Solution is not just a tool - it's a comprehensive ecosystem designed to enhance your logistics operations, delivering accuracy, efficiency, and reliability. Choose Asset Flow Management powered by Lyngsoe LIVE Logistics™ for complete visibility and control of your assets across your network and supply chain.

Ready to gain complete visibility and control of your assets?

Contact us today for a personalized demo and discover how our solution can transform your operations.

Explore More Solutions