Lyngsoe Conveyor Systems: Automated Sorting Technology for Smarter Library Logistics

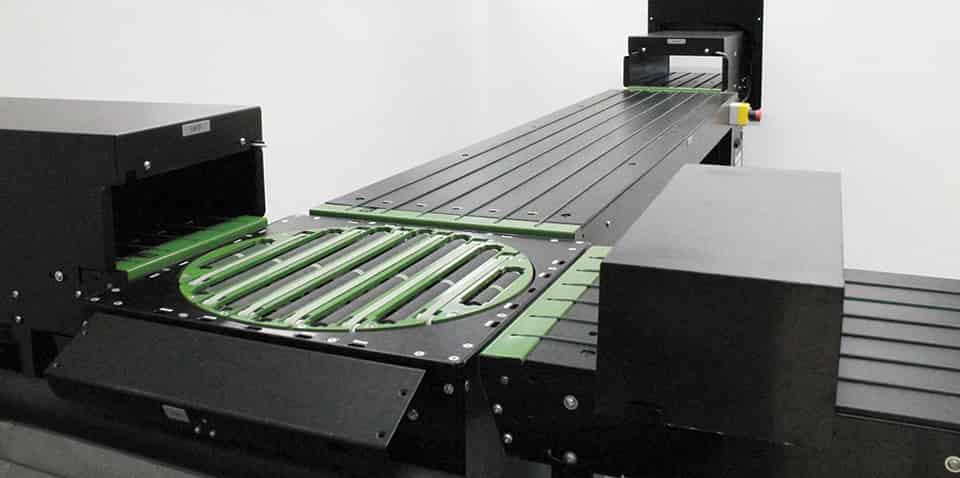

Lyngsoe Conveyor Systems are an integral part of the Lyngsoe Sort Mate™ 2000 series, which enables you to automate returns and elevate your library operations. Say goodbye to manual handling and hello to a streamlined, cost-effective, and efficient circulation system.

Discover the Benefits of Lyngsoe Conveyor Systems

Integrating with Sort Mate 2000 reduces staff handling and repetitive tasks while ensuring a smooth, easy experience for patrons

Maximise your library’s footprint with adaptable conveyors that effectively handle elevation changes, optimizing space across multiple floors

Boost efficiency with conveyors that support multiple lines in a central sorter, enabling faster circulation of library materials

Automated material handling revolutionizes your library’s operations, increasing speed while reducing costs

Start Your Next Chapter in Library Innovation

Get in touch to find out more about how our tailored solutions can help your library reach its full potential.

See What Others Are Interested in

Turn mate

Optimize your library's workflow with Turn Mate. This system effortlessly redirects items during the sorting process, ensuring a smoother operation.

Split Chute

Maximize sorting efficiency with Split Chute. This solution directs returned items to multiple destinations, streamlining your workflow like never before.

Sort Mate

Enhance your sorting capabilities with Sort Mate. This versatile system takes the complexity out of sorting library materials, making it faster and more.

Library Case Stories

From Manual Handling to Streamlined Efficiency

As Marigold Library System faced growing volumes, the Sort Mate™ 2000 proved invaluable in streamlining sorting and improving daily workflows.

Automation Increases Meaningful Patron Time

When Svendborg Library decided on an automatic book sorter, the decision was rooted in a desire to improve working conditions for staff as their circulation numbers rose. With the sorter, manual labor was decreased while the staff gained time for more meaningful patron interactions – something the library believes will secure their survival in the future.

Managing Growing Return Numbers with Automated Book Sorting

As Nørrebro Library continues to experience a rise in their circulation numbers, the implementation of a small sorting system onsite has been invaluable to the functionality of the library.

Numerous Benefits to Automating the Library Return Process

“The partnership with Lyngsoe Systems was very service-oriented. We were able to rely on the team’s professional and competent advice during both the planning and implementation of Lyngsoe’s products.”

Automatic Book Return in Dortmund

The library’s customers had no problems at all with the new return machines, so there was very little need for support from the start.

Ergonomics on a Big Scale

“Odense Libraries have achieved a better physical working environment due to fewer or almost no heavy lifting. This implies employee satisfaction and the expectation of fewer days of sick leave.”

Curious about our solutions and how we can unlock the potential of your library?

Frequently Asked Questions

Can Lyngsoe Conveyor Systems be used for both check-in and hold fulfillment?

Yes, items returned via the Conveyor System are automatically checked in and routed to the appropriate destination, whether that be reshelving, a specific department, or a hold shelf. For items on hold, the system can prioritize sorting to designated bins or carts for rapid pick-up preparation, minimizing staff handling and supporting library automation.

How configurable/scalable are Lyngsoe Conveyor Systems?

Our options are extremely flexible. You can start small (e.g., with just a few sorting destinations) and expand later. Modular conveyors and modules adapt to your space and circulation volume, from compact branch libraries to large central facilities.

Can Lyngsoe Conveyor Systems handle elevation changes or multi floor setups?

Yes, specialized elevation modules enable conveyors to navigate vertical changes. Items can move between floors or zones to support your material sorting without the need for manual transport.