Designing an AMH System

The Lyngsoe Sort Mate™ 2000 AMH system is modular by design. It consists of a range of standard products, which can be connected in a multitude of ways to fit the needs of libraries of all sizes – and rooms in odd shapes.

To get started, we recommend considering the following:

Defining the needs – Patron perspective

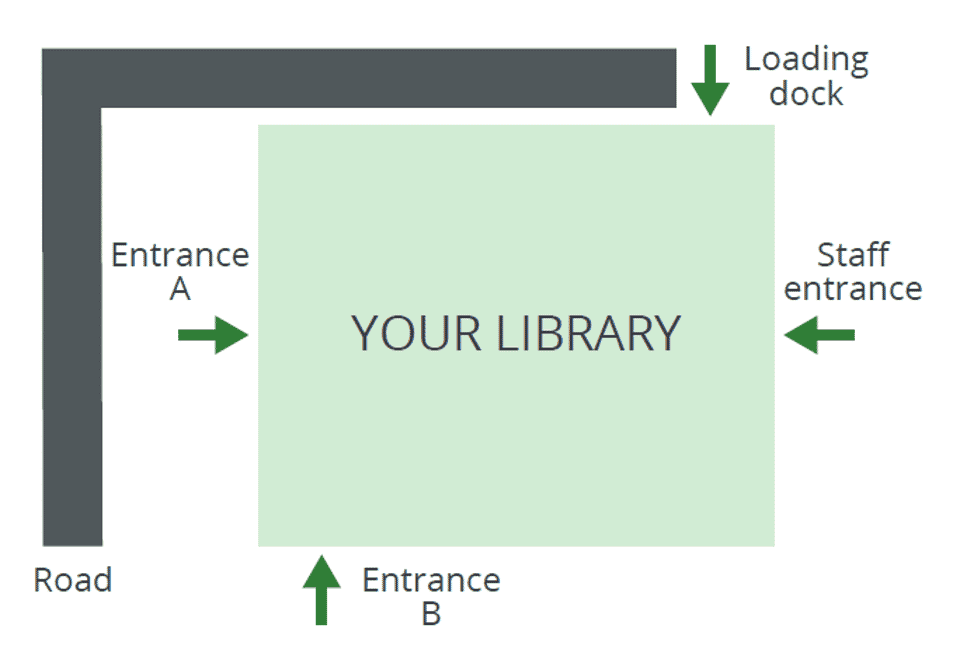

Sketch out: How and where does your library welcome the patrons?

When you introduce automated returns, they will become part of the welcome and service you give. It should be easy for patrons to return their items, so consider:

Should there be an exterior return/induction to allow for returns 24/7/365? If so, is it a drive-up or walk-up, which is e.g. allows for wheelchairs to access?

Should the patrons be able to return items inside the library? If so, where would it be natural to place the return from the patrons’ perspective?

Often patrons will also be picking up holds/reserved items, so consider if you can place returns and holds strategically to guide patrons through your library.

Defining the needs – Library, operational perspective

Your imagination, space, and budget set the limits, so it is important for you to consider your minimum needs and aspirations. Lyngsoe sorters operate close to unattended, except when the containers at destinations need to be emptied.

- How big is your daily number of returns?

- Which categories would you like to split/sort them into?

- How often do you want to empty containers, be it totes, trolleys, or carts?

Naturally, the more destinations, the more capacity, but if you are not able to fulfill your aspiration year one due to budget restraints, the modularity allows you to add more later on, but you should consider the available space from the beginning.

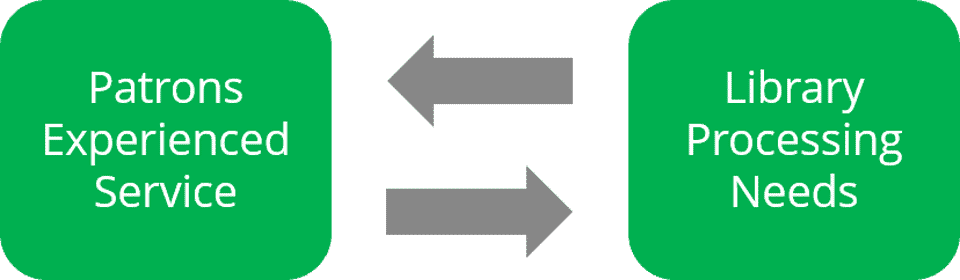

Match the two perspectives and Sketch out the Structure

Compare the two perspectives. Maybe they are a perfect match. If not, you should rank your wishes and decide on the final requirements.

With those in hand you can start to sketch out, how you want to structure your new sorter in terms of placement, induction and destinations.

Let us help you

Get in touch with our project managers and sales team to get an expert opinion on your individual project.

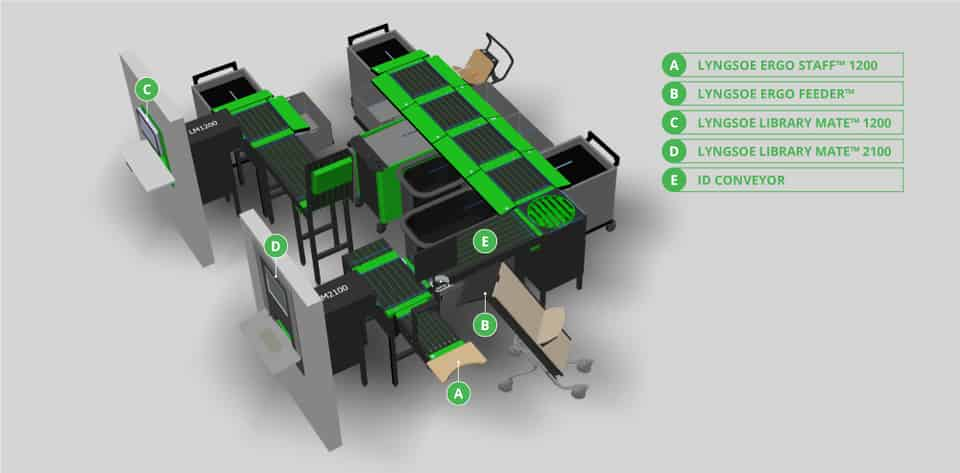

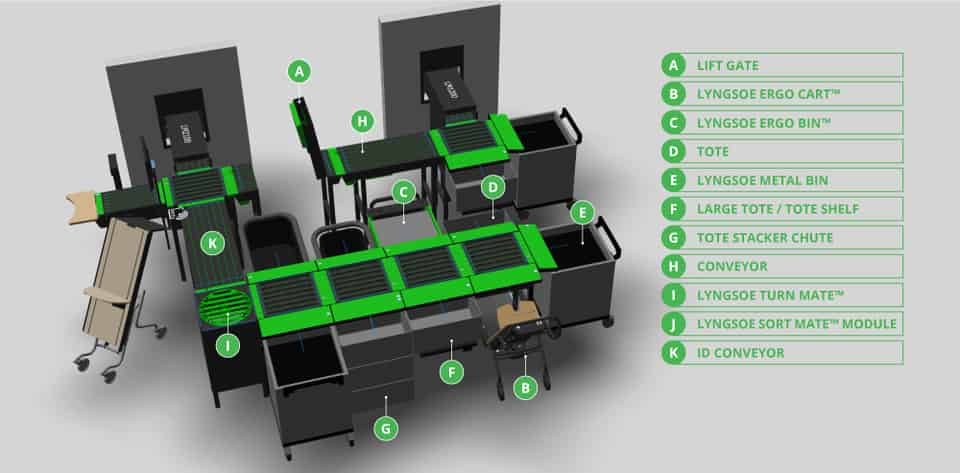

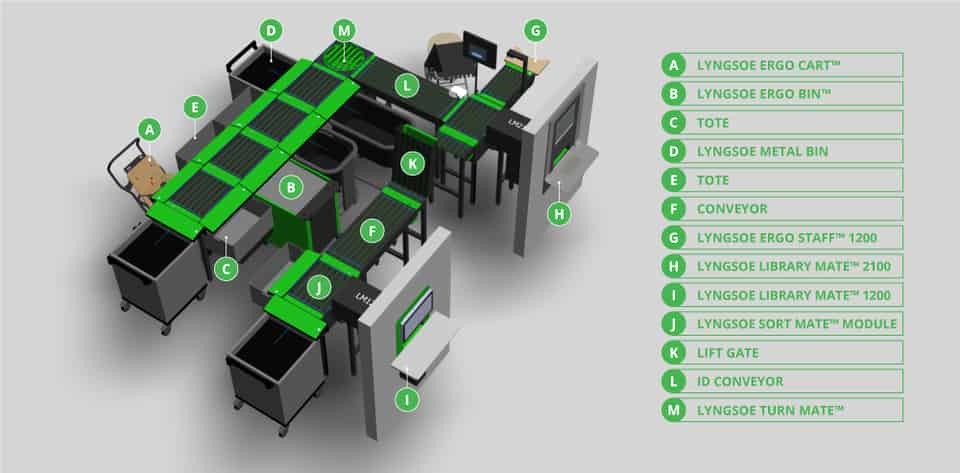

Basic structure of a library sorting system

When you choose the Sort Mate™ 2000 Automated Material Handling System from Lyngsoe Systems, you have a wide range of tested and tried options at hand. The returns (or inductions) are the interface to the patrons, so they are designed to be intuitive to use both in terms of physical design and in the software user interface on the screen.

Options to fulfil your needs - Inductions and Destinations

Options are available both for external inductions, i.e. inductions placed on the outside of the library space, and interior inductions placed inside the library space.

The destinations are for staff purposes, but equally important to consider. Also here a wide range of options present themselves both for the branch library, the main library, and for a dedicated central sorting facility. All using the same base module, but with destinations and their containers to fit the specific purpose and needs.

Like the actual sorting, the process starts with selecting the inductions for the system.

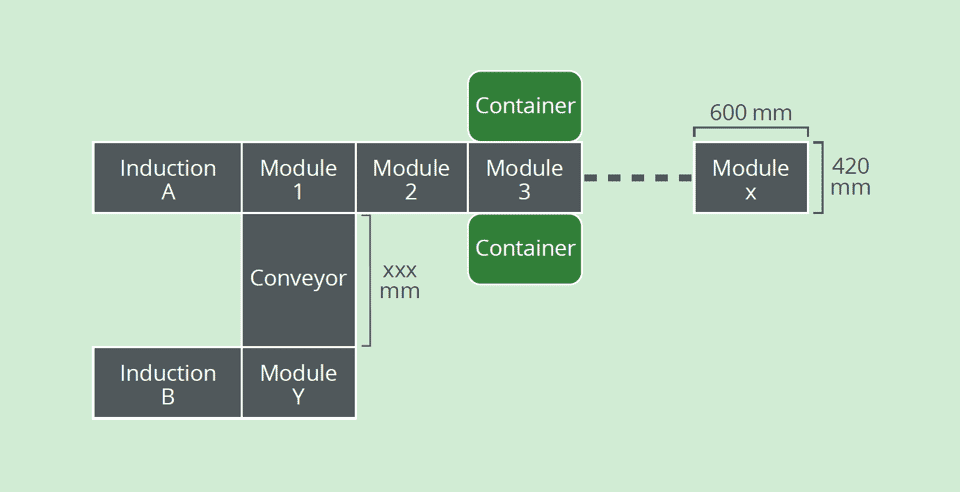

Modules and Conveyors can be placed in a multitude of ways. Modules have a fixed size, while several lengths of conveyors are available to be flexible to different physical surroundings.

Do you consider a 24/7 walk-up or drive-up outside the building, an exterior induction (or return) is needed? If you need high induction capacity or uninterrupted access for members of staff, a dedicated staff induction is a good choice. Inductions contain the Lyngsoe Library Mate™ software communicating with the ILS/LMS to check items in.

We can separate the inductions, or inlets, into three major types: Exterior, interior, and for staff. In the Lyngsoe Sort Mate system, they would be called Library Mate™ 2100, Library Mate™ 1200, and Ergo Staff, respectively.

The more inductions for patrons, the more can be served at the same time without people having to stand in lines. You should determine, what is an acceptable service-level for the library and its patrons.

An exterior induction is potentially available 24 hours a day. It can be placed to serve as a walk-up or drive-up. If access determines that it must be installed away from the main sorting function, the distance can be bridged by conveyors. Or it can be installed as a stand-alone, and staff will bring the returned items to the sorter.

If your library needs high induction capacity, receives significant amounts of items from other branches to sort, or uninterrupted access for members of staff, a dedicated staff induction is a good choice to place on a module.

Library Mate™ 2100 - Exterior patron induction

Library Mate™ 1200 - Interior patron induction

Library Mate™ 5000 - Height-adjustable, interior patron induction

Ergo Staff™ 1200 - Fast and ergonomic staff induction

Ergo Feeder™ 2000 - Automated induction of items

BISR – Singulator - Automated singulation of bulk items

Manual book drop for your library automated material handling

The Sort Mate™ 2000 modules are the building blocks for the sorting function. Some are used for changing the direction of an item, while others are the actual sorting destinations. The assigned destination is controlled through the Library Mate and/or Lyngsoe Sorter Controller software.

Deciding your destination needs

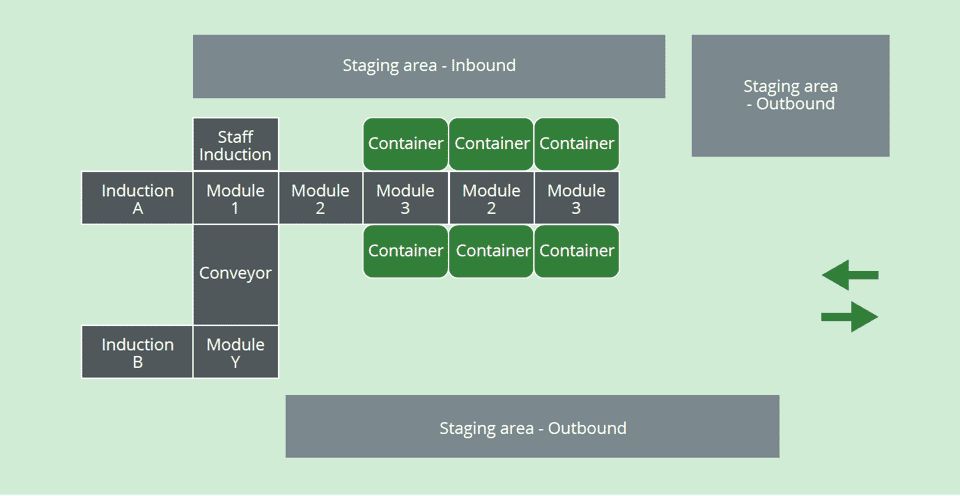

When designing the sorting function, you should consider the process happening around it as well. Typically, there will be a need to store full containers/receptacles, until the content can be processed, or to store empty containers nearby to quickly switch, when one runs full.

The more destinations, the finer the sorting, and the less the need to have staff allocated to handle the sorter. If placed at a distance, conveyors can connect the inductions to the space relevant for the sorting function.

You have a number of choices in the Lyngsoe sorter system. Stationary or movable bulk solutions. Transport totes. Ergonomic carts. All to adapt to your logistical processes around sorting.

The basic building block is the Sort Mate™ module to which the different destination/receptacles options are added. The conveyors let you bridge distances at speed, if the inductions and the sorting function need to be located separately.

As part of product safety we have the E-Stop (Emergency Stop) button, which will stop the system immediately when pushed. Lyngsoe Systems’ recommendation is that there are no more than 2.1 m to the closest E-stop button anywhere in the solution. National safety regulations can vary.

You are welcome to contact us at Lyngsoe Systems for a review of any of your layouts as a quality control before submitting a bid or a purchase order.

Sort Mate™ Module Reliable building- block for your AMH

Lyngsoe Conveyor - Fast, reliable conveyance of items

Lyngsoe Ergo Bin™ -Ergonomic, moveable bulk destination

Ergo Cart™- Ergonomic transport directly from library sorter to shelf

Lyngsoe Turn Mate™-Turning book spines

Split chute enables precise automatic library sorting -Two destinations on one chute

Tote Shelf - Collapsable for increased flexibility

Work Smarter and Design Your Own Lyngsoe Sorter

Lyngsoe Systems is always happy to listen, advise, and design a system layout optimized to your needs and available space. Contact us today to start your journey of automating your sorting