Case Story: Auckland Libraries

“TE WHEKE“ - the largest central sorter in the southern hemisphere

About Auckland Libraries

Auckland Libraries is the public library system for the Auckland Region of New Zealand. It was created when the seven separate councils in the region merged in 2010. It is currently the largest public-library network in the Southern Hemisphere with 56 branches spread over 5,000 square kilometers, serving a population of nearly 1,600,000 residents. The library’s Collection Development Policy has four guiding principles reflecting Auckland’s diverse communities; commitment to Māori knowledge; commitment to the principle of freedom of access to information and applying the best value for the people of Auckland to purchasing and managing the collections.

The circulating collection of the library contains 2,700,000 physical items with 10,000,000 – 12,000,000 physical items checked out per year.

"Now that Te Wheke is happily working away, our journey takes us back to the beginning: planning for IMMS. This really will be our giant step forward into the future."

Karen Harbers

Manager of Acquistitions and Supply Chain

The challenge

Amalgamation of seven councils requires focus on consistency

Central sorters are to be found in many library systems around the world, however, the Auckland Public Libraries relied on manual sorting for their 56 libraries until December 2021. Following the amalgamation of the seven councils in 2010 the library’s focus has been on ensuring consistent practice in one Council, which has been a huge, but important task.

Enormous volume of material being hand sorted

The enormous volume of material moving around the libraries‘ network of branches has created many pain points. The principal among these is that the manual process requires printing and inserting a ‘transit slip’ indicating each item’s destination.

This takes staff time, risks causing repetitive strain injuries, and creates high volumes of paper waste as the transit slips are discarded when the items arrive at their destinations.

IMMS™ becoming of interest

The journey to the sorter began somewhat

unexpectedly. Catherine Leonard, Head of Library and Learning Services, heard about the integration with Sierra (Auckland’s Library Management System) of software designed to assist collection management.

The Intelligent Materials Management System (IMMS) enables libraries to remotely control the volume and range of material sent to branch libraries resulting in an allocation of material suited to each library’s profile, higher return on investment, less crowded shelves, a reduction of superseded items distributed, and less front-line staff time spent manually balancing collections.

Researching IMMS and how it is working in northern European libraries where it has been in place for several years led to several conversations with the Danish developers, Lyngsoe Systems. In these discussions, it became apparent that for Auckland, the first step had to be to purchase a sorter in order for IMMS to work as efficiently as it is intended.

The solution

The biggest sorter in the southern hemisphere

The Auckland Libraries are now the proud owners of Te Wheke – (te reo Māori for “the Octopus” Appropriate for something with ‘arms’ or ‘tentacles’ in constant motion), a Lyngsoe SortMate, supplied by Lyngsoe’s Australasian agent, FE Technologies.

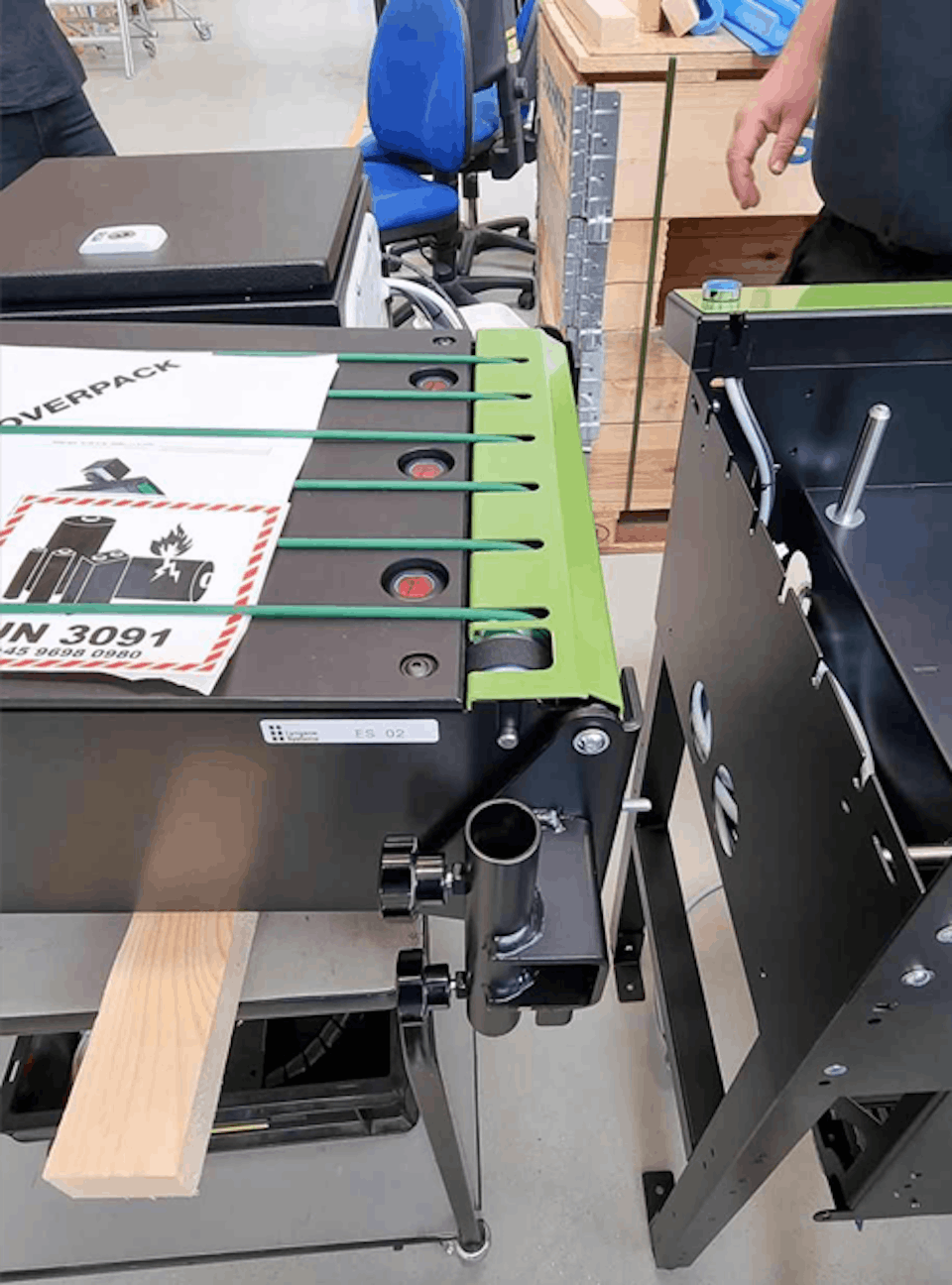

Buying a piece of equipment like a sorter takes time and Te Wheke required several ‘tentacles.’ Preparing the business case for funding was just the start. The biggest decisions were about its design and where it would be housed. Ultimately, the library decided on a 41-bin Lyngsoe sorter, not just because of its obvious compatibility with IMMS, but due to its speed, low operating noise, and most importantly, its high uptime.

Sorters usually operate within libraries, but Te Wheke needs 250m2 of floor space with room for spare parts, totes, dump bins, conveyors, and pallet lifting equipment as well as the necessity of being close to the motorways and having all-weather vehicle access. The library liaised with their logistics partner, Urgent Couriers, for their expertise and equipment for managing high material volumes. Urgent had been operating the library’s manual sort facility for the past five years along with delivering all of Auckland Council’s mail and courier services. A more positive, can-do partner would be hard to find!

External challenges

Global pandemic put an end to tested practices

The order for the large sorter was made through FE technologies to Lyngsoe Systems in early 2020, with the assumption that it would be produced in Denmark, shipped to New Zealand and when shipment had arrived in Auckland, a Danish Lyngsoe Engineer would fly down and do the installation. However, before the parts were ready to ship, the worldwide COVID-19 pandemic caused both Denmark and New Zealand to go into lockdown and any thoughts of traveling across the world became impossible dreams.

Fat testing in Denmark

Now the Danish engineers had to think out of the box as Lyngsoe Systems prides itself on delivering in the promised time. The solution was to create a plug-and-play delivery. This was done by setting the entire sorter up 100% as it should have been done in Auckland but at the Lyngsoe Systems headquarters in Aars, Denmark. The sorter had its FAT (Factory Acceptance Test) done and was fully commissioned before taking it all apart, leaving the components as fully assembled as possible before packing everything in numbered containers ready for set-up on the other side of the world.

“When the world turned upside down, we realized we needed to think completely out of the box and go further than ever before to create a smooth project implementation within the new reality.”

Carsten Toft, Project Manager from Lyngsoe Systems

External challenges

Collaboration across borders

1 October was an exciting day when the Seasmile carrying Te Wheke arrived at the Port of Auckland. After unloading, border clearances, transportation, and unpacking, installation could finally begin on 12 October. COVID-19 lockdown in Auckland meant that the final installation work was contracted to a local company working via remote instruction by Lyngsoe Systems partners, FE Technology based in Melbourne, Australia.

All went smoothly and by Friday of that week all of the components were in place and a digital connection to Te Wheke was made enabling configuration and testing to begin.

Training and fine-tuning adjustments were made so that when the libraries re-opened post-COVID Te Wheke could be put through her paces.

With COVID restrictions in Auckland easing Auckland Libraries were finally able to celebrate Te Wheke’s arrival into their whānau with a small ceremony, on 10 December.

However, the final calibration had to wait until the Australian FE engineer involved in the remote setup was allowed entry into New Zealand in April 2022.

What made it possible:

- Thorough preliminary factory acceptance testing and after sales support provided by the Lyngsoe Systems team in Denmark.

- Conjoint project management efforts actioned by David Riches (FE Technologies) and Karen Harbers (Auckland City Council).

- System Integration and performance enhancements by Eliza Richards (Auckland City Council) and Aaron Paap (Auckland City Council).

- Venue preparation, hardware deployment and a “Can do attitude” provided by Deane Tetley and the team at Urgent couriers.

"This deployment was quite the ride in such trying times and is certainly in my personal top 5 projects that I have worked through."

Clint Agustsson

FE Technologies

Benefits

350,000 items sorted the firtst month

The volume of material moving around the libraries’ network is high. Between 8,000 and 12,000 items per day transit to the 56 libraries. Achieving a 24-hour turnaround to sort this volume is a task worthy of Sisyphus.

Te Wheke proved to be invaluable within days after being switched on as a record 350,000 items were sorted that November, which was not a full month of library operations due to lockdowns.

The immediate benefits were clear:

Paper transit slips were no longer required, moving the library closer to its sustainability goal. Reduced staff time and less manual work; it is possible to run Te Wheke for 12-hour days while dealing with the backlog after lockdown, something people could not be expected to do. Most of the suppliers now send shelf-ready new material directly to Te Wheke enabling library customers to receive their requested items faster.

The results

Less repetitive strain on staff

Today Te Wheke sorts up to 28,000 items a day, running quietly and stably throughout its operation hours. Staff experience markedly less strain on hands and shoulders and find it very easy to change from one sort table to another when necessary for fine sorting to the smallest libraries in the system.

"We’re very proud of the collaborative effort with all of our partners that resulted in the sorter being installed during the disruptions and constraints of the past two years. It has felt like a journey of shared vision and faith. Now we’re looking forward to the implementation of IMMS to really transform our processes and free staff time to work on designing and delivering services that will have a positive impact for customers and communities."

Catherine Leonhard

Head of Library & Learning Services

Explore our Products and Solutions

Automated Material Handling

Simplify your library operations with Automated Material Handling. Enjoy faster returns, seamless sorting, and improved overall efficiency.

Self Service Equipment

Empower your patrons with our Self-Service Equipment. From easy check-outs to efficient returns, make every library visit a seamless experience.

Intelligent Material Management System

Take control of your collection with IMMS. From data-driven insights to ergonomic handling, transform the way your library manages its resources.